Hot Sale Factory Guide: Glass Mosaic Tiles Manufacturing Process

Specializing in the Glass Mosaic Tiles Manufacturing Process, I offer high-quality tiles that are perfect for your next project. Our Hot Sale items highlight the breathtaking designs and vibrant colors that can transform any space. Each tile undergoes a meticulous manufacturing process in our well-equipped factory, ensuring durability and style in every piece. With years of experience, I understand what B2B purchasers like you are looking for—affordable, trendy, and reliable products that won't let you down. Whether you're aiming to create luxurious interiors or stunning outdoor landscapes, my glass mosaic tiles are a perfect fit. Let’s elevate your projects together with tiles that combine artistry and craftsmanship. Trust me, when it comes to Glass Mosaic Tiles, you won’t find a better partner than us. Reach out, and let’s discuss how we can meet your needs and exceed your expectations.

Glass Mosaic Tiles Manufacturing Process Industry Leaders Custom Solutions,

In the dynamic world of interior design, glass mosaic tiles have emerged as a popular choice for turning ordinary spaces into extraordinary ones. The manufacturing process of glass mosaic tiles combines artistry with advanced technology, ensuring that each piece is not only visually stunning but also durable. From the selection of high-quality raw materials to the meticulous cutting and sizing of the tiles, every stage of production is designed to meet the highest standards. Leading manufacturers in the industry embrace innovative techniques, such as water jet cutting and automated assembly, to enhance precision and efficiency while minimizing waste. For global buyers seeking custom solutions, the flexibility in design options is a key advantage. This includes a wide range of colors, patterns, and finishes to perfectly align with diverse aesthetic preferences and project requirements. Whether it's for residential applications, commercial spaces, or large-scale architectural projects, manufacturers are equipped to provide tailored mosaic tile solutions that cater to specific needs. By collaborating closely with clients, they ensure that the end products are not only functional but also reflect the unique vision of the project. Investing in high-quality glass mosaic tiles is not just about aesthetics; it’s about creating lasting value. The durability and ease of maintenance of these tiles make them ideal for various environments, from bathrooms and kitchens to pool areas and feature walls. As trends evolve, staying ahead in this competitive industry requires a commitment to innovation and quality. For procurement specialists, finding a reliable partner that can deliver custom-designed tiles backed by exceptional service will guarantee successful project outcomes and satisfied clients.

Glass Mosaic Tiles Manufacturing Process Industry Leaders Custom Solutions

| Process Step | Description | Materials Used | Quality Control Measures | Customization Options |

|---|---|---|---|---|

| Raw Material Selection | Choosing high-quality glass for durability and aesthetics. | Colored glass, recycled glass, and specialty glass. | Visual inspection for defects. | Color matching and glass type selection. |

| Cutting & Shaping | Glass is cut into specific shapes and sizes. | Glass sheets or tiles. | Precision cutting checks. | Custom shapes and sizes per order. |

| Surface Treatment | Surface polish and finish to enhance shine. | Finishing compounds and sealants. | Random sampling for gloss levels. | Textured and smooth finishes available. |

| Packaging & Shipping | Final packaging to ensure safe transportation. | Protective wraps and boxes. | Integrity checks before sealing packages. | Custom packaging options offered. |

| Post-Sale Support | Assistance with installation and maintenance. | Installation kits and manuals. | Customer satisfaction surveys. | Tailored support based on customer needs. |

Related Products

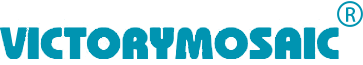

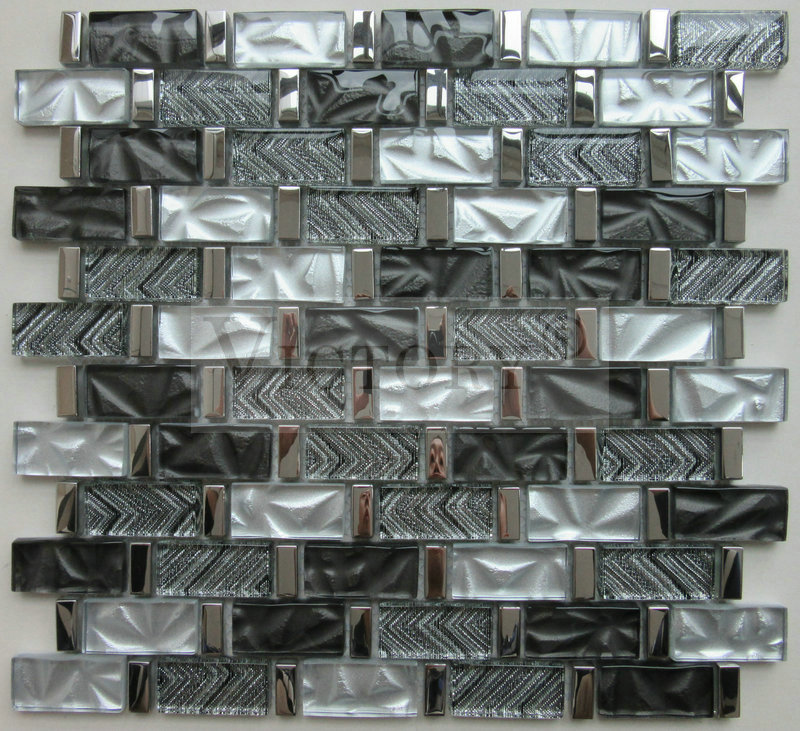

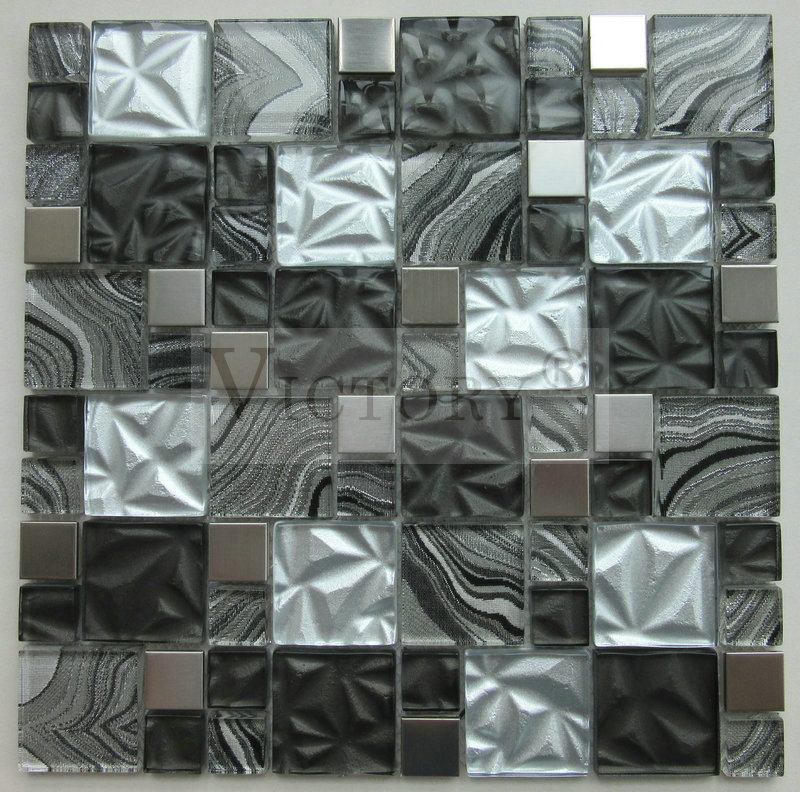

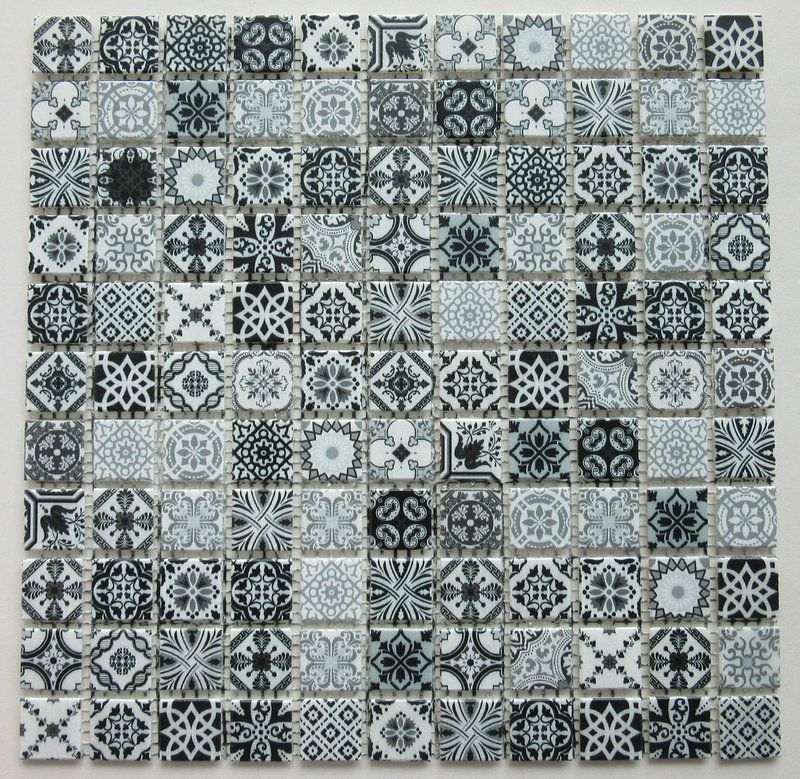

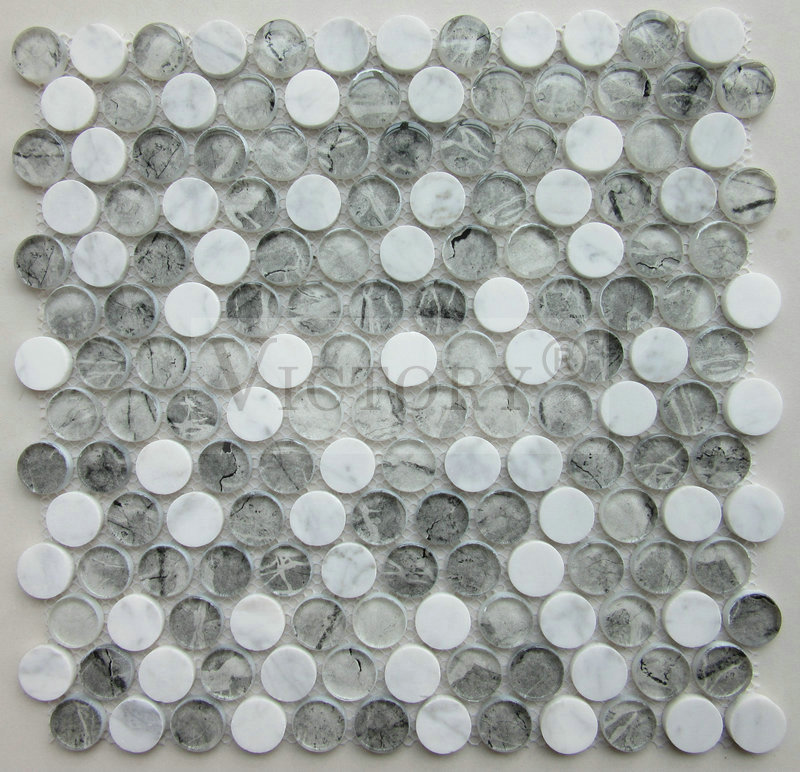

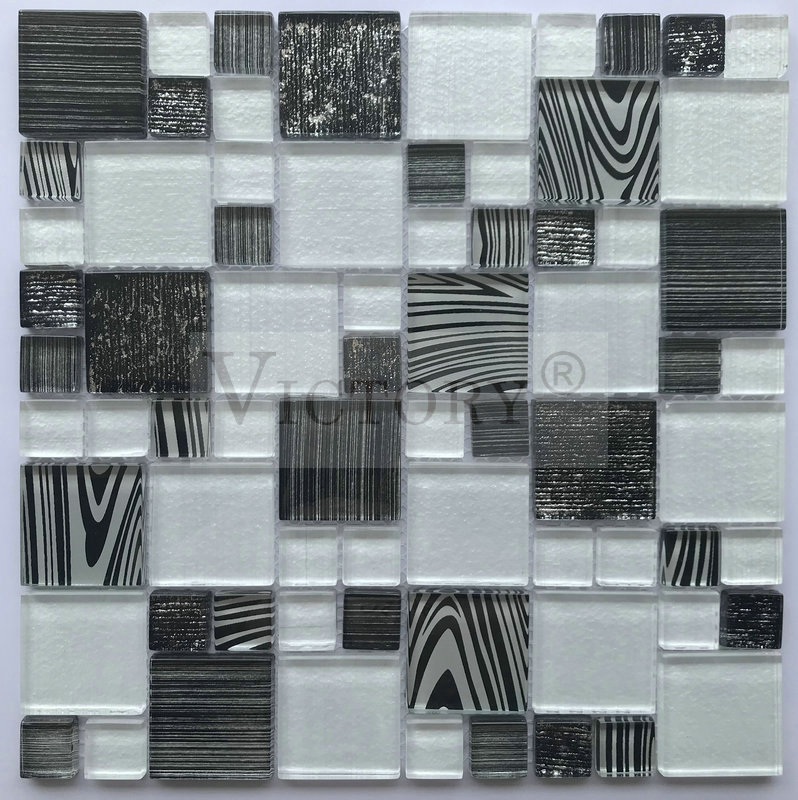

China Victory Laminated Glass Mosaic Tiles Metallic Mosaic Bathroom Tiles 12 x 12 Mosaic Tile

Read More