Mosaic Tiles Manufacturing Process: Hot Sale from Our Factory

Are you in the market for high-quality mosaic tiles? Our hot sale mosaic tiles are crafted through a meticulous manufacturing process that ensures each piece combines durability with stunning designs. As a dedicated factory, we understand the value of providing unique products that elevate any project. From the initial selection of raw materials to the precision cutting and vibrant glazing, every step in our mosaic tiles manufacturing process is handled with great care. I personally oversee the production to guarantee that you receive only the best. Whether you're working on a large-scale project or a smaller renovation, our tiles are sure to impress and meet your aesthetic demands. Partner with us, and let us help you bring your visions to life with our exquisite mosaic tiles. Reach out today and experience the difference quality materials can make.

Mosaic Tiles Manufacturing Process Industry Leaders Your Trusted OEM Partner

The mosaic tile manufacturing process represents a fusion of artistry and advanced technology, catering to diverse aesthetic demands around the globe. Industry leaders have honed their techniques to ensure that each tile reflects durability, creativity, and precision. From the careful selection of raw materials to the final quality checks, every step is meticulously executed to guarantee a product that meets stringent international standards. As a trusted OEM partner, we offer comprehensive support for global buyers looking to source high-quality mosaic tiles. Our state-of-the-art facilities are equipped with the latest machinery, allowing for the efficient production of tiles in various styles, shapes, and colors tailored to specific market needs. Moreover, our commitment to sustainability ensures that our processes minimize environmental impact while maintaining the exceptional quality our clients expect. Working with an experienced and reliable partner can streamline your procurement process and enhance your product offerings. By choosing an OEM that understands the dynamics of the mosaic tile industry, you can benefit from innovative designs and a seamless supply chain, ultimately driving your business growth and satisfying your customers' evolving tastes.

Mosaic Tiles Manufacturing Process Industry Leaders Your Trusted OEM Partner

| Tile Type | Material | Production Method | Color Options | Standard Size (cm) |

|---|---|---|---|---|

| Glass Mosaic | Glass | Casting | Blue, Green, Red | 2x2 |

| Ceramic Mosaic | Ceramic | Extrusion | White, Yellow, Gray | 5x5 |

| Porcelain Mosaic | Porcelain | Pressing | Black, Beige, Brown | 3x3 |

| Natural Stone Mosaic | Stone | Cutting | Gray, White, Multicolor | 10x10 |

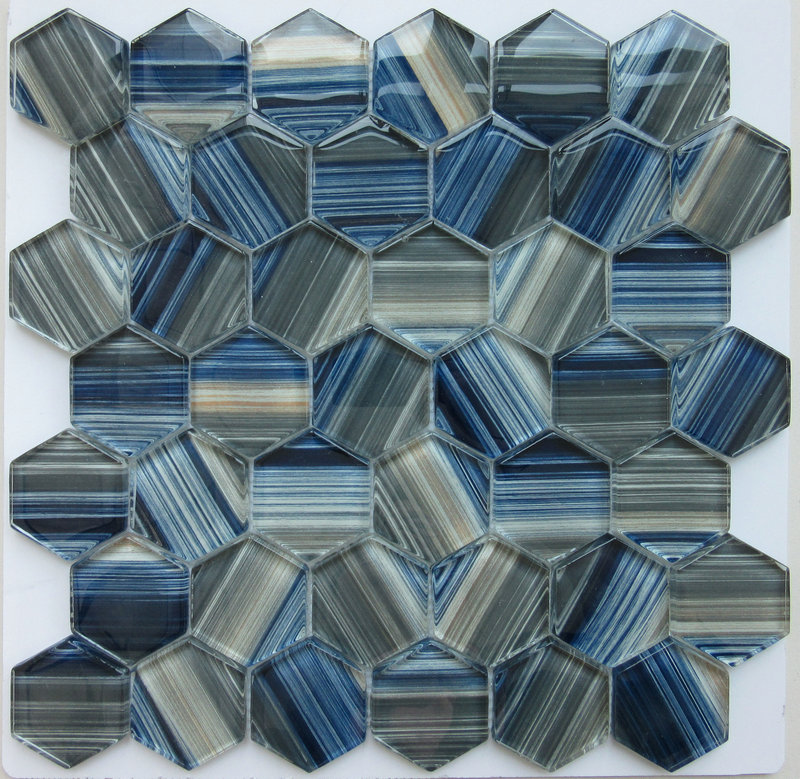

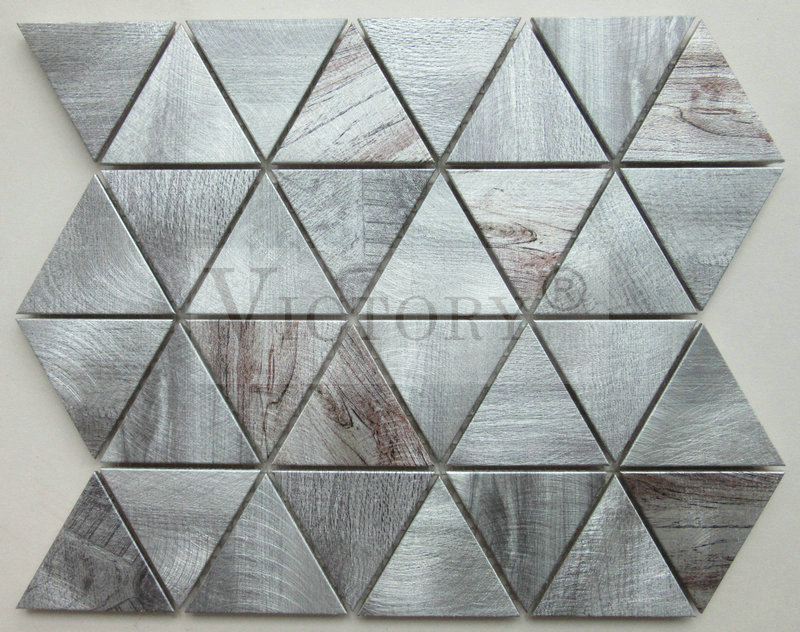

| Metal Mosaic | Metal | Casting | Silver, Gold, Copper | 2.5x2.5 |

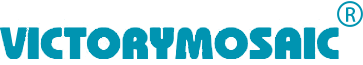

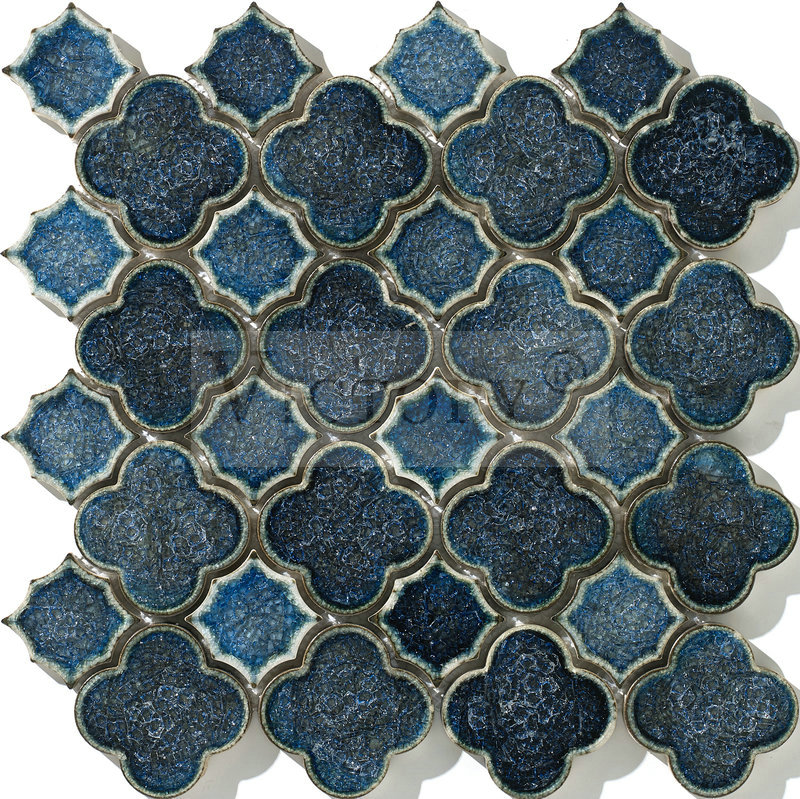

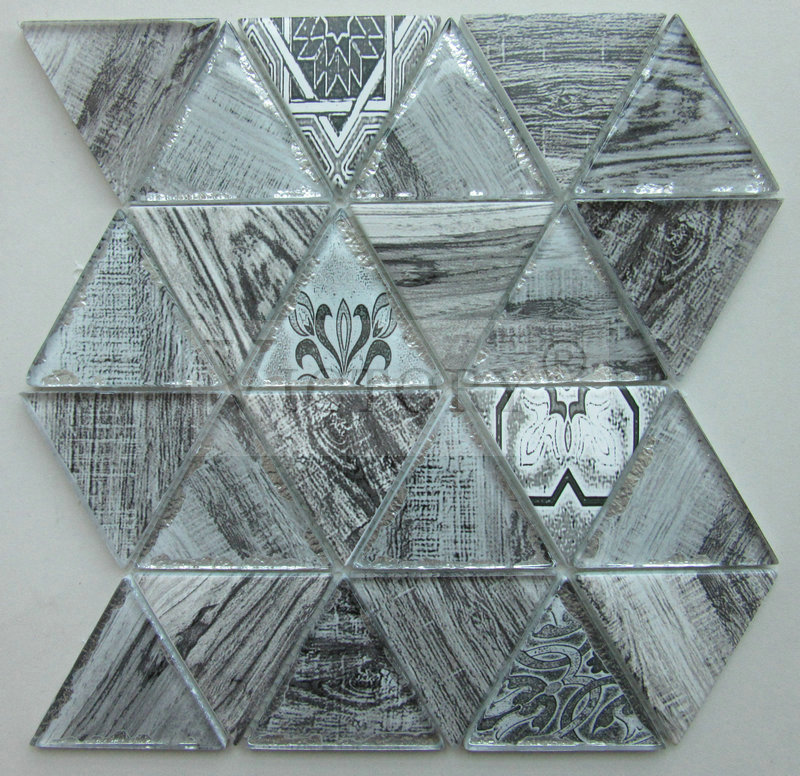

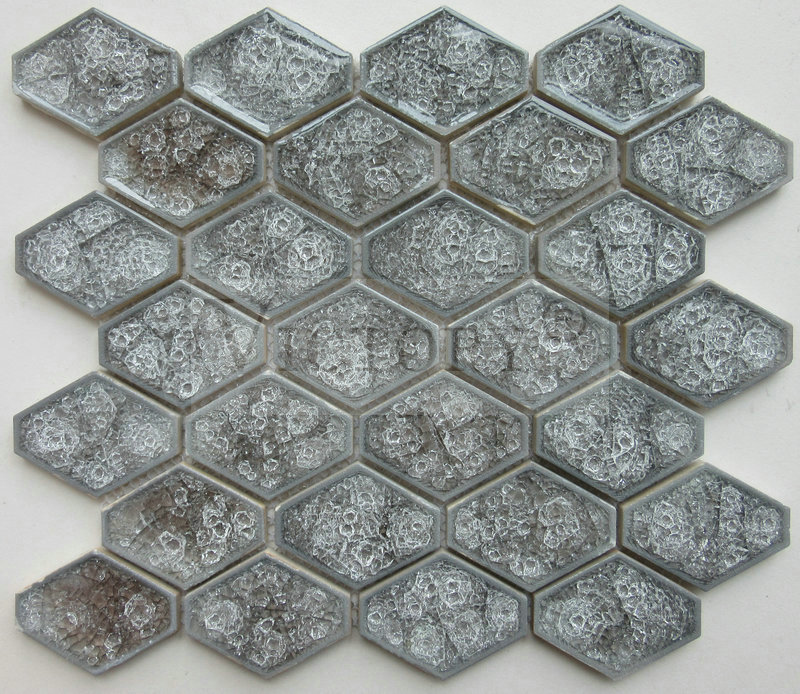

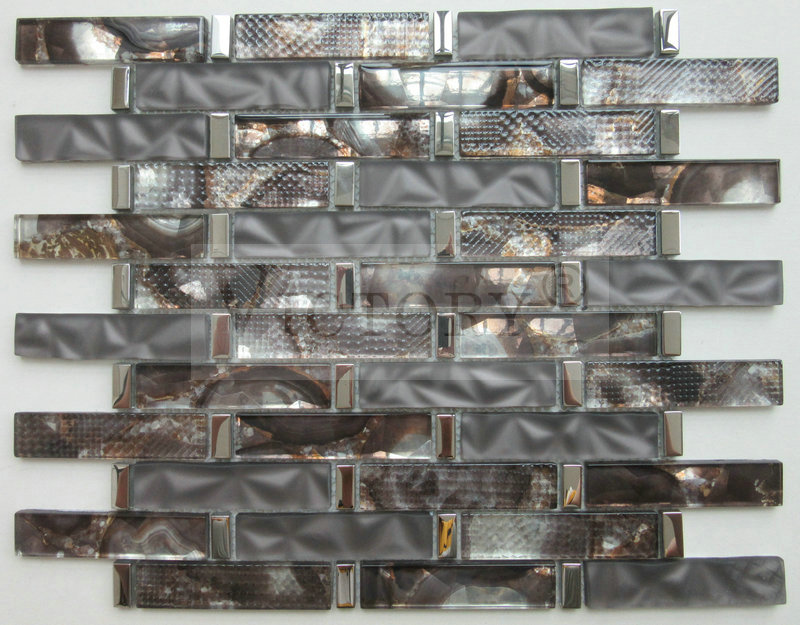

Related Products

China Victory Water Jet Mosaic White Mosaic Tiles Marble Mosaic Backsplash Waterjet Brass Inlay White Stone Mosaic

Read More